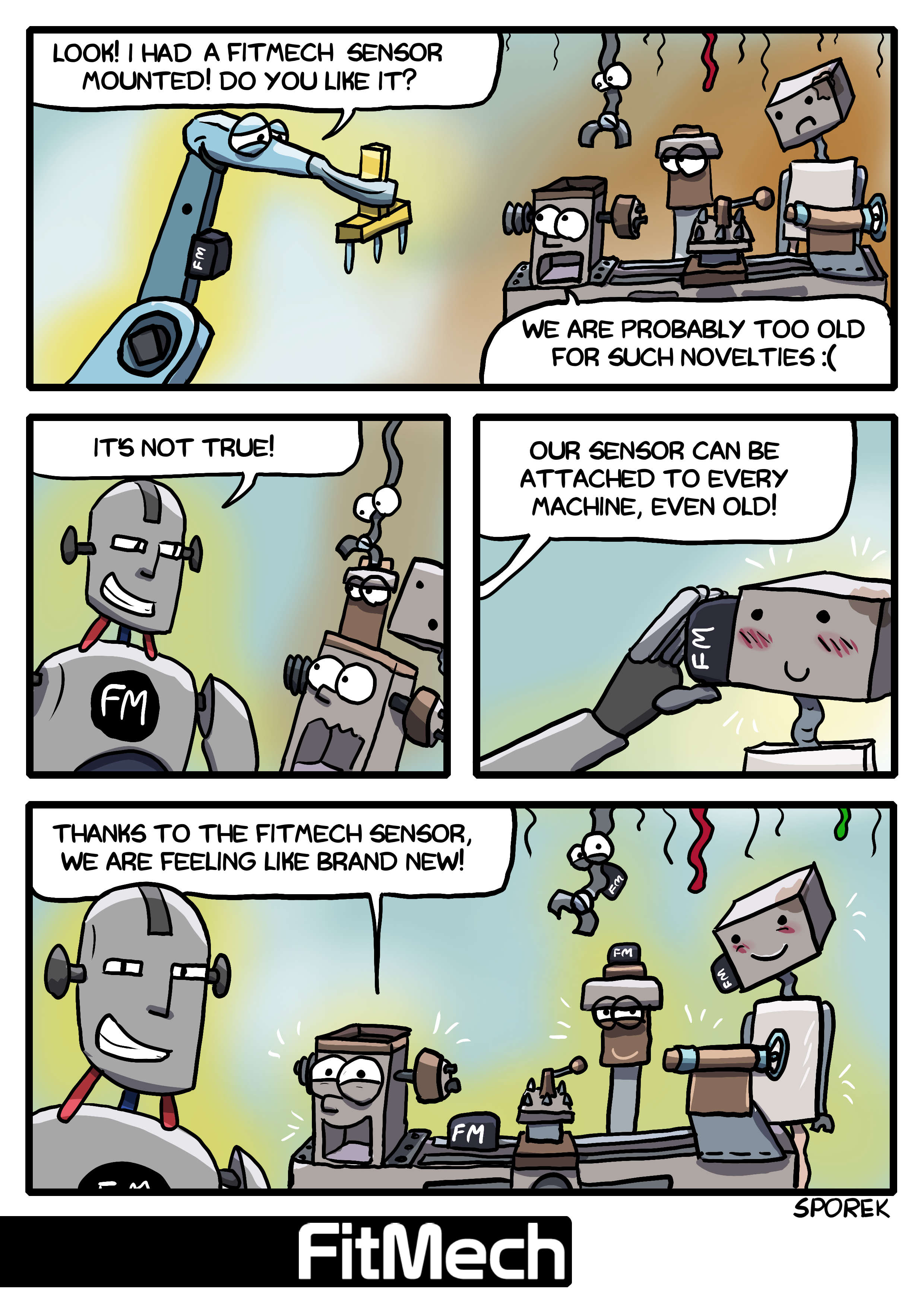

Problem

How to obtain data from older, non-computerized machines?...

...without incurring the costs of their modernization, expanding the existing infrastructure and interfering with controllers of the devices?

Solution

FitMech provides analytical data on the operation of any machine, using non-invasive sensors that measure the movement and vibrations generated during their operation.

Automatically, in a private cloud and without the burden of maintaining additional infrastructure!