How FitMech works?

Like an industrial stethoscope...

Sensors installed on machines are like a stethoscope - they measure vibrations and accelerations happening during machine operation

Data from the sensors are sent out to computing cloud via wifi

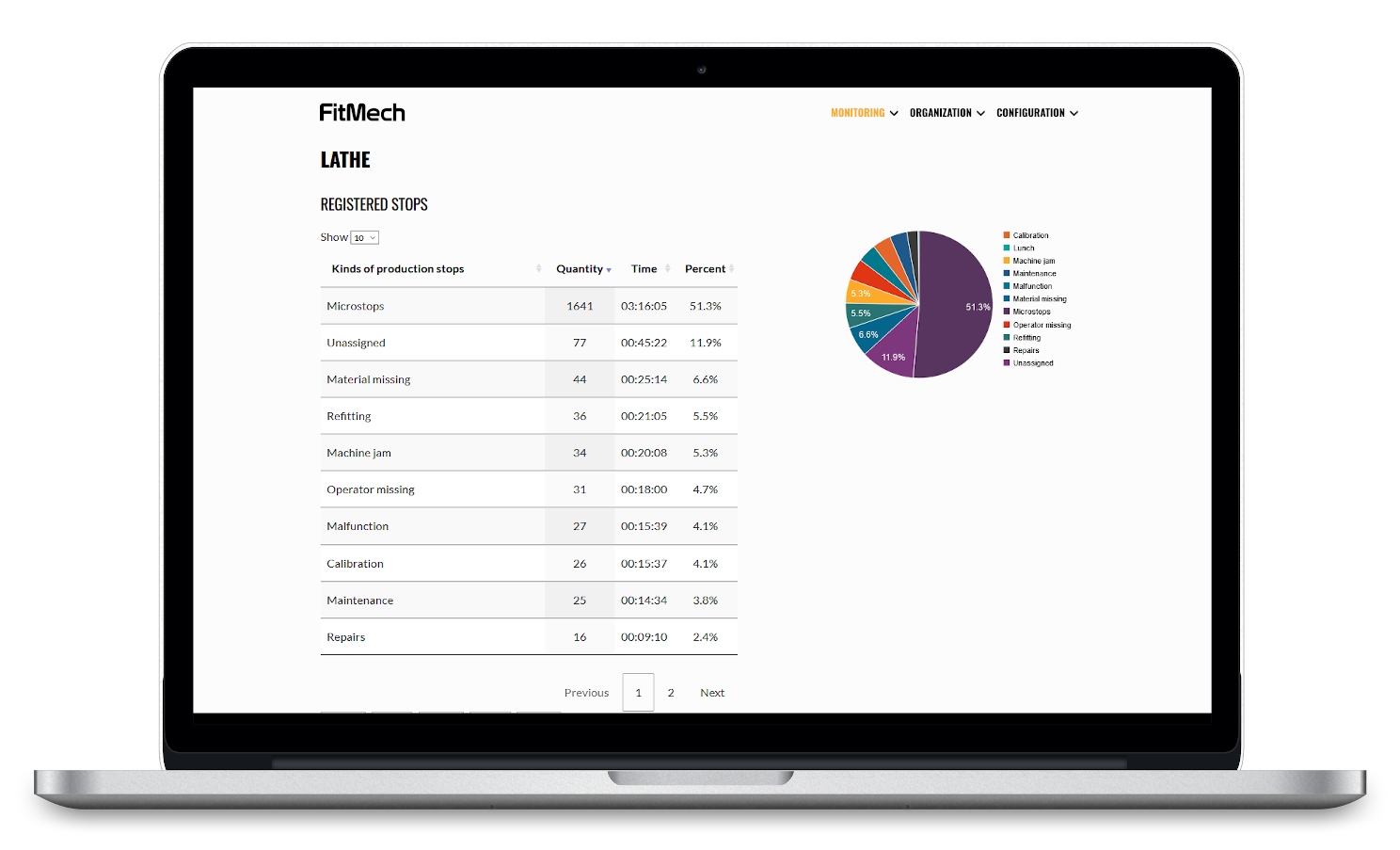

Computing cloud processes data from the sensors: identifies machine's status, detects work cycles, downtimes and more

Operator's Panel helps flagging reasons of detected downtimes

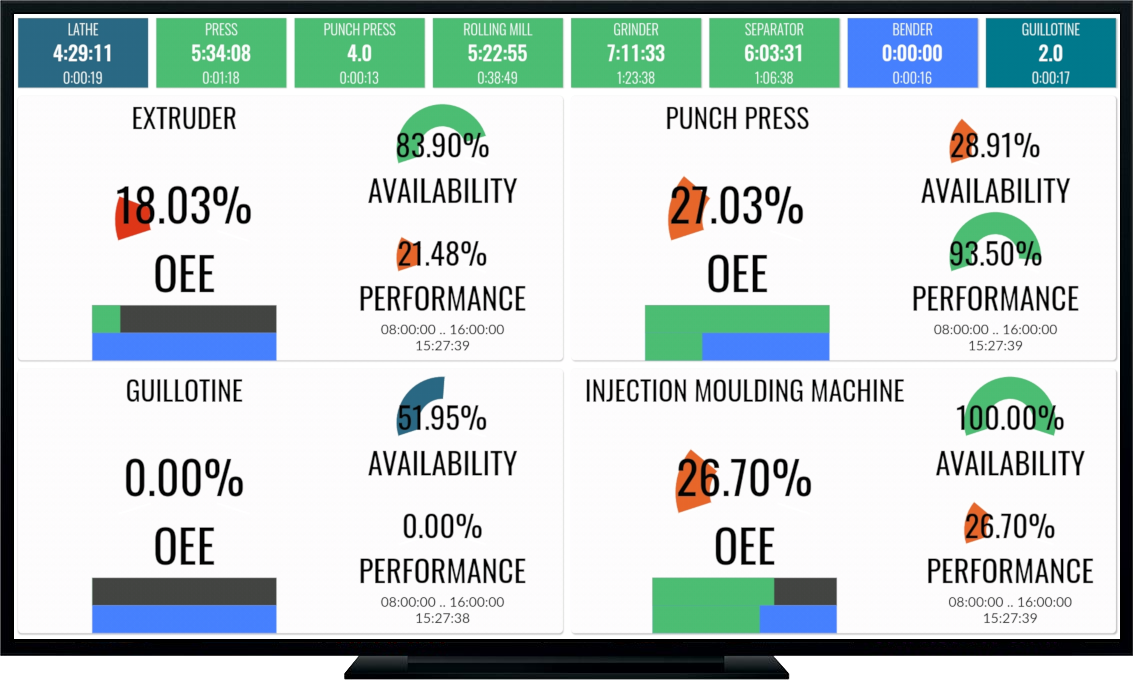

Current production data are presented on the andon board display

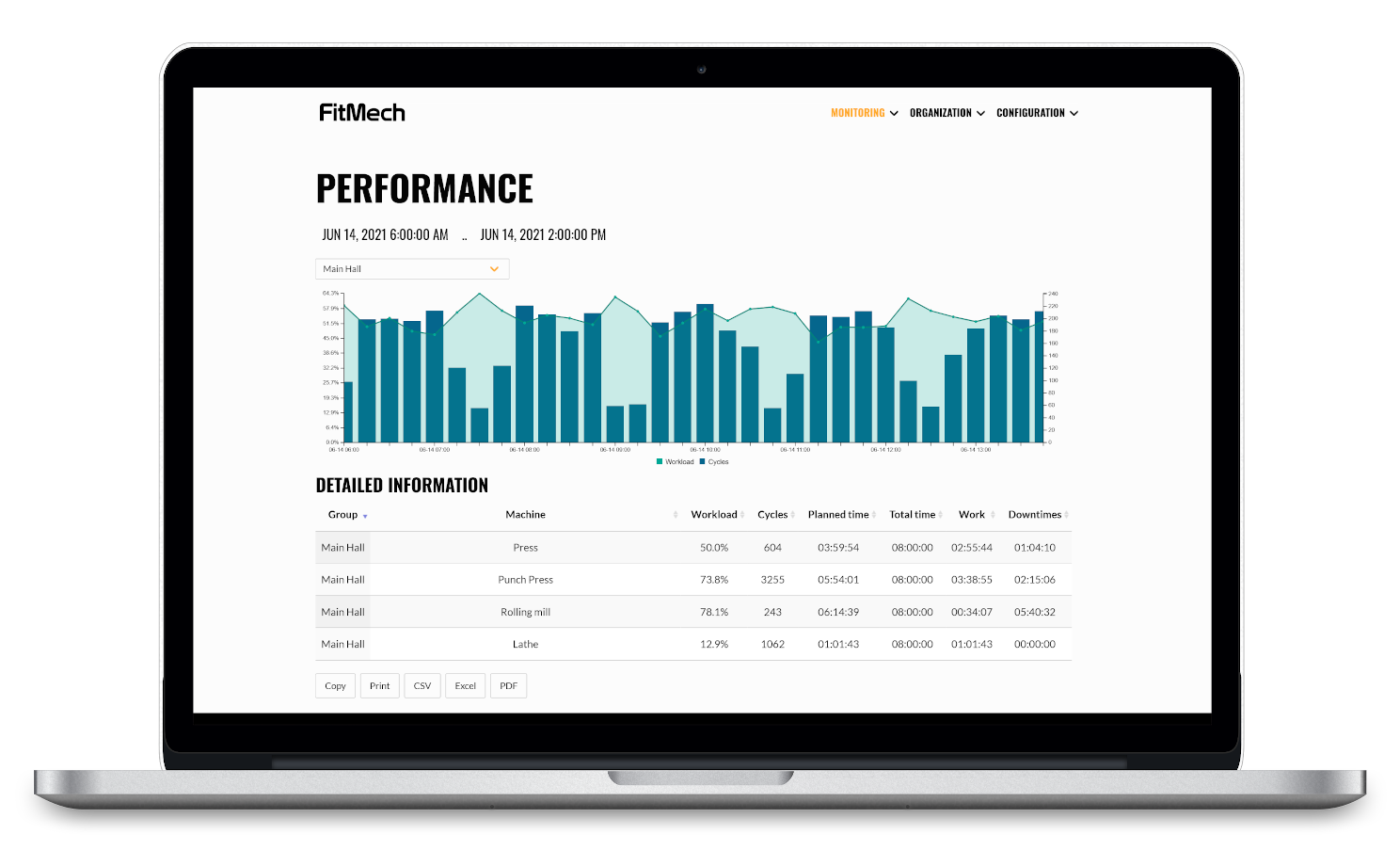

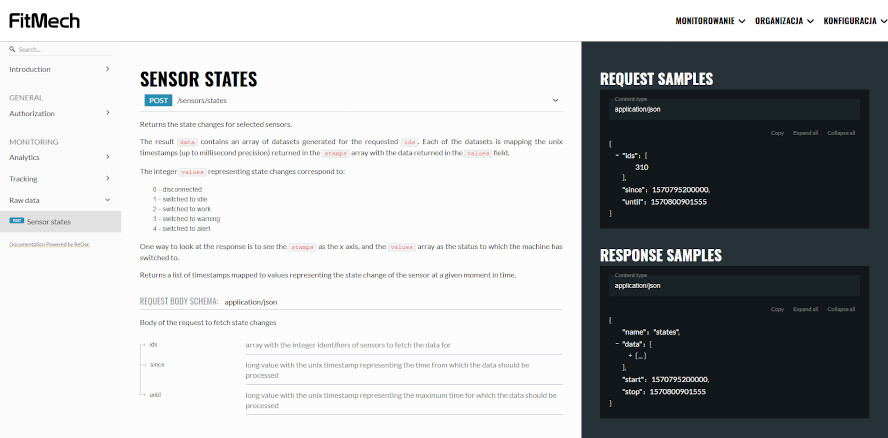

Analysis outcomes, in the form of live preview and historical reports, are presented in the online panel and mobile app