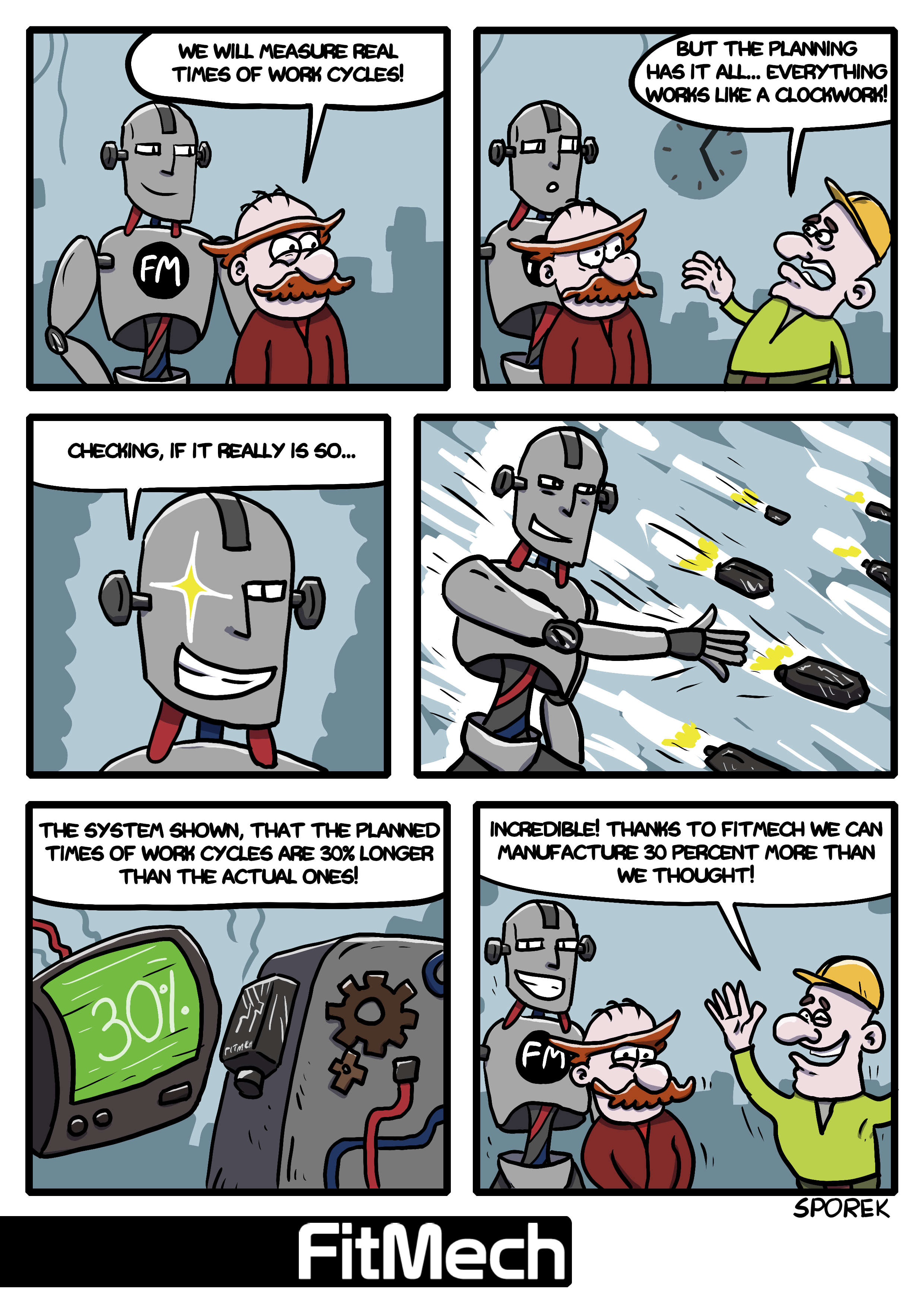

Problem

How to measure the actual times of machines' production cycles and get a real picture of the production process in order to be able to effectively optimize it?...

...without burdening the operators with additional administrative tasks related to the production of documentation or carrying out time-consuming and costly gemba observations?

Solution

The FitMech system collects data automatically and online: cycle by cycle, shift after shift, day by day - eliminating the need to keep paper documentation and drastically reducing the time of access to information.

FitMech allows you to make decisions based on real, objective data, instead of relying on declarative reports and, often, biased opinions.