Who we are and what we do?

Technology provider

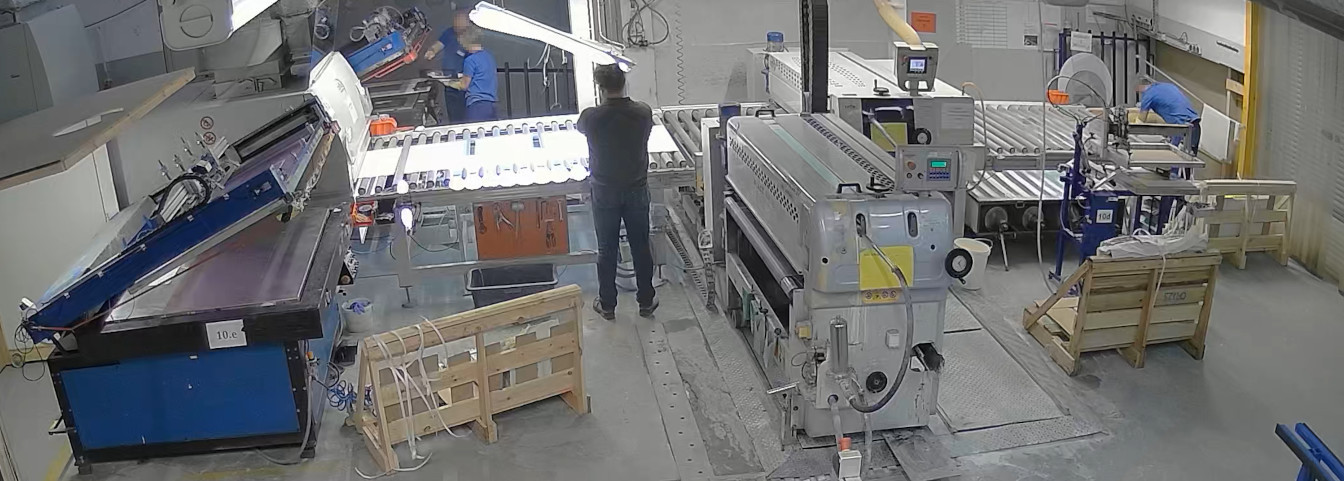

"We began our cooperation with FitMech during an optimization project carried out for our client from the glass industry. The aim was to identify the most frequent and costly downtime and to define the operating standards of the machine park.

We decided to use FitMech because of easy implementation and the data provided, e.g. duration of production cycles, statistics of efficiency and downtime of each of the tested machines. FitMech automated the collection of this data, increased its volume and provided visualizations.

Having a much more complete picture of how the production processes are carried out, we were able to conduct a more detailed analysis of the organization and provide it with better recommendations for optimization.

The end result of the three-month project was a list of improvement activities - both technical and organizational. We expect that their implementation will bring the customer a 30% increase in factory efficiency over the next year. "